WORLDWIDE NAME IN POLYMER PROCESSING

For more than 60 years, Belgian family business Bekina has been working to create real added value. We strive for worldwide leadership by focusing on craftsmanship, quality, innovation and sustainability in the development of polymer solutions. We do this for various sectors and niche markets spread across our four business units.

Bekina in figures

125+ employees

8 different nationalities

600+ customers

80+ countries

2600+ products

800 raw materials

40 million euro turnover

Milestones

Bekina was founded in 1962. It all started with Bekina Boots, a producer of rubber boots that later began making polyurethane safety boots for professionals. More than 60 years and three generations later, the Bekina group of companies continues to innovate and grow. The Group now includes not just Bekina Boots but also Bekina Indurub, Bekina Compounds and Bekina BeSealed. Bekina guarantees a long-term future vision, generation after generation.

Founding of Bekina Boots by Denis Vanderbeke

Second generation: Georges Vanderbeke

Founding of Bekina Indurub

Switch from rubber boots to polyurethane boots

Founding of Bekina Compounds

Third generation: Thomas Vanderbeke

Founding of BeSealed

SEE OUR DETAILED HISTORY

2024

BeSealed becomes Bekina BeSealed

BeSealed becomes Bekina BeSealed

As part of a broader initiative to harmonize our company names, the BeSealed name was changed to Bekina BeSealed in 2024. We also got a new logo, in line with the other company logos. This rebranding affirms our collective ambition to strengthen the group’s reputation and guarantee the trusted quality that the group offers every day.

2024

Expansion of sustainable infrastructure

Expansion of sustainable infrastructure

Sustainability is a top priority for Bekina and we try to put that into practice in everything we do. 2024 marks an important milestone in our sustainable story with the transformation of our company car park and the installation of a large number of solar panels on our roofs. The new car park is future and climate proof. The car park has been extended with extra parking spaces (for cars, bikes and motorbikes), 20 charging points, lots more green features and improved permeability.

2023

Migration to new ERP package: SAP

Migration to new ERP package: SAP

Innovation is in our DNA. That’s why we’ve upgraded our data system to a new ERP package called SAP. The SAP package forms a robust backbone for our data processing and guarantees better transparency throughout the Bekina Group. The data migration from the old to the new system was a major undertaking, and it took time for our employees to adjust to the new digital environment too. The effective cooperation and hard work put in by everyone in our team was a great demonstration of our Bekina Values (specifically Engagement).

2022

60 years of Bekina

60 years of Bekina

2022 is an important milestone for Bekina. This year we celebrated our 60th anniversary! We have been working hard to produce the highest quality polymer solutions for a wide range of sectors all around the world for 60 years. To celebrate this milestone, we organised a big Bekina birthday party for our colleagues, friends, family, neighbours and other stakeholders.

2019

Introduction of RFID technology

Introduction of RFID technology

Bekina is focusing more than ever on innovation. This has resulted, among other things, in the introduction of RFID technology at Bekina Boots. RFID stands for radio-frequency identification. Every pair of boots is fitted with an RFID tag as standard. This is a unique identification for that exact pair of boots. The technology offers numerous possibilities and helps to ensure optimisation of our production process. Thanks to the RFID tag, we can trace and analyse the boots’ journey from production to end customer, resulting in improved quality control and therefore improved quality.

2017

Growth as a sustainable organisation

Growth as a sustainable organisation

Bekina is a pioneer in various areas, including the field of sustainability. Even before the general trend towards sustainability in the business world, Bekina already had a strong focus in this area. Paying attention to both people and planet has always been an important part of our company philosophy. In 2017, Bekina began cooperating with Voka (the Flemish network of enterprises) to create a sustainability policy. As the largest enterprise network in Flanders, Voka helps companies to grow and blossom together. Voka's action plan is aligned with the United Nations’ 17 sustainable development goals. Since then, the number of sustainable initiatives at Bekina has only increased.

2017

NEOTANE

NEOTANE

We developed our own polyurethane, called NEOTANE. This is a high-quality material especially developed by Bekina Boots as an application of polyurethane (PU) for our professional safety boots. It's a unique combination of components that together form a polyurethane foam structure. The chemical reaction between the different components creates a sustainable product consisting of multiple layers and minuscule air bubbles, which results in: light and flexible boots, optimal thermal insulation and good breathability.

2014

Founding of BeSealed

Founding of BeSealed

The common thread running through Bekina's company history is the spin-off activities and presence in different niche sectors. In this respect, the founding of the brand BeSealed was our fourth bull’s eye. BeSealed brings products to the market for watertight concrete constructions in the building sector. The hydrophilic profiles are produced by Bekina Compounds, and Bekina Indurub supplies the moulded products for various complex sealing problems. A great integration of all our know-how!

2013

Move to the new offices

Move to the new offices

Bekina moved into its brand-new offices and lab. Daylight, transparency, comfort and sustainability are the keywords at this striking piece of architecture. The lab, with state-of-the-art measurement and testing equipment, ensures we can test the quality of our products every day. We also work with renowned testing institutes around the world in this area.

2012

Installation of sprinklers

Installation of sprinklers

Safety is a top priority for us. That’s why we installed a sprinkler system in our buildings. This is a fixed fire-extinguishing installation to detect fires at an early stage, raise the alarm and manage and/or extinguish them. The installation uses sprinkler heads on the ceiling, which start working when needed. Particularly in light of our company fire in 1987, this is a very important investment for us.

2008

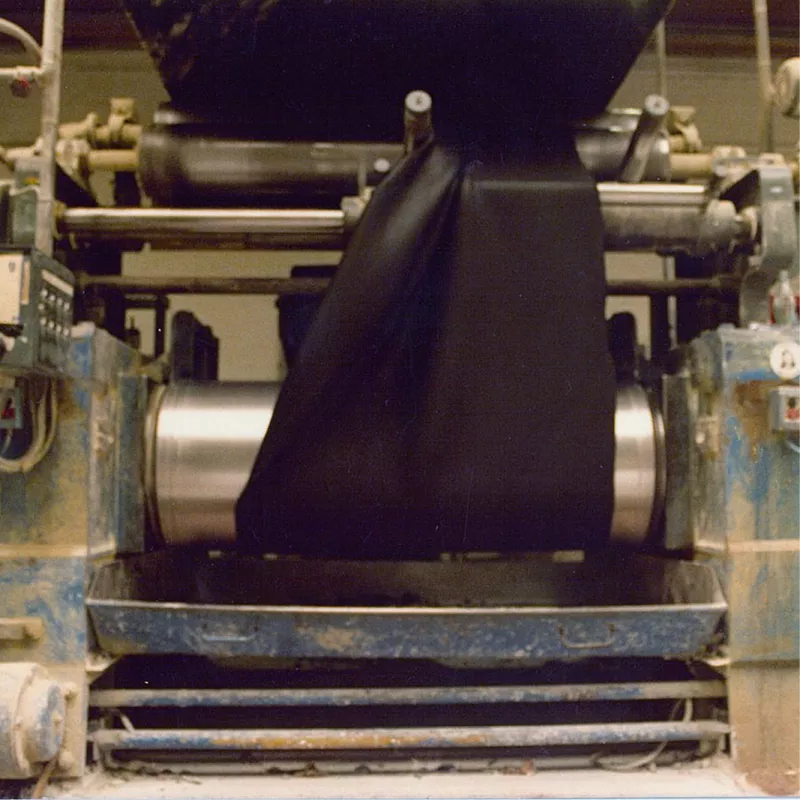

Expansion of Bekina Compounds

Expansion of Bekina Compounds

Bekina continues to grow and this resulted in a new building that serves as a warehouse for Bekina Compounds, allowing us to expand our stock capacity. New machines were also added, delivering automation of our processes. Bekina Compounds evolved with the addition of the AZO mixing system and iCom mixing technology. With our AZO mixing system, we can add up to 7 fillers and 4 fluids to the rubber mixes. iCom is our own patented mixing technology, which ensures homogeneous, pure and reliable quality.

2004

Thomas Vanderbeke, third generation

Thomas Vanderbeke, third generation

Thomas Vanderbeke, Georges’s oldest son and also the third generation of boot makers, joined the Bekina team. From the start, he focused on effective marketing, process optimisation, product innovation and sustainability. Looking to the world and the future, he is committed to making a big difference in even the smallest details. Innovation and quality remain central to his policy.

2000

Expansion

Expansion

Bekina Boots and its sister company, Bekina Indurub, grew so fast that Bekina Indurub soon moved into its own brand-new 5000 m² production facility. Based across the road on the opposite side of Berchemstraat, production stayed close to home.

1994

Founding of Bekina Compounds

Founding of Bekina Compounds

While we previously only made rubber compounds for internal use, Georges made the decision to establish Bekina Compounds as a separate activity. This company specialises in the production of coloured rubber compounds, made to the customer’s specification. From the beginning, a conscious choice was made for coloured compounds, always with specific properties and produced to the customer’s specification.

1990

Switch from rubber boots to polyurethane boots

Switch from rubber boots to polyurethane boots

The Vanderbeke craftsmanship is characterised by a relentless drive for improvement. After Georges learned of the benefits of polyurethane (PU) at an international trade fair, there was no stopping him. A new era had begun: Bekina started production of polyurethane boots. Bekina boots were lighter, more comfortable, better insulated and more durable as a result. In comparison with rubber or PVC boots, our PU boots are 40% lighter and last three times longer. One small step for man, one giant leap for Bekina.

1989

TPE & SBS

TPE & SBS

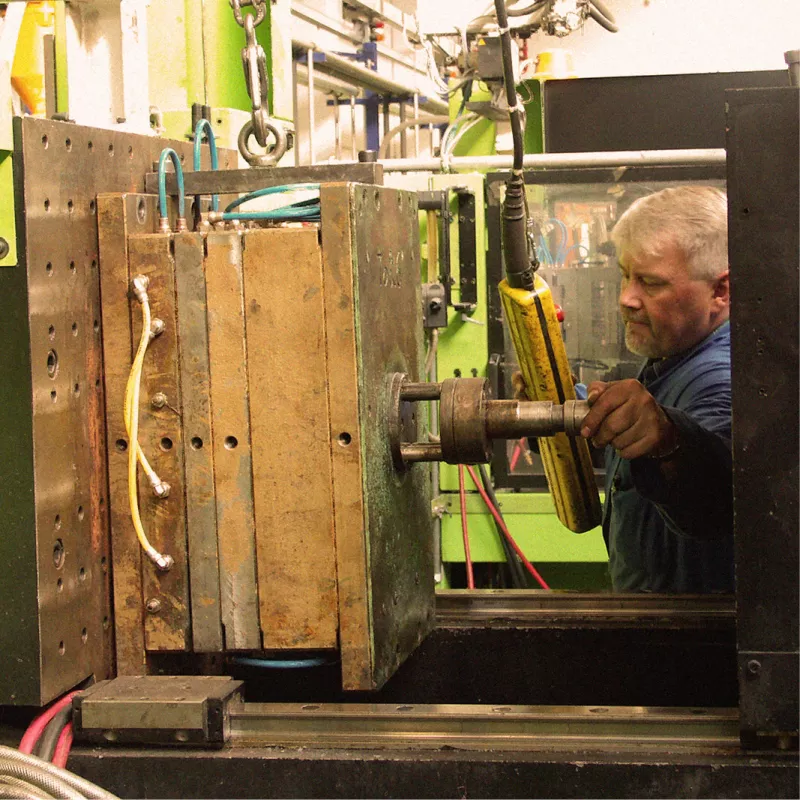

Bekina Indurub started as an injection moulder of innovative rubber products but, from the early nineties, we switched to thermoplastic elastomers (TPEs). We make polymer products for a wide range of niches, in various polymers including SBS, SEBS, TPE Light and TPE-E.

1987

Devastating fire

Devastating fire

As the only manufacturer of rubber boots in Belgium, Bekina Boots was busy preparing for its 25th anniversary celebrations. But then, on 24 October 1987, disaster struck. A terrible fire reduced the entire business to ashes in a single night. Everything was destroyed and had to be rebuilt. Luckily, all the employees helped willingly to rebuild the business. Thanks to their joint effort, Bekina was fully operational again just eight months after the fire. The company returned with the same staffing, production and sales levels as before the fire, but in a brand-new building.

1984

Further internationalisation with Georges

Further internationalisation with Georges

With his language skills, flair and commercial talent, Georges continued to expand Bekina into the international market. From 1984, Bekina Boots began to be exported further and further afield, even outside Europe. He organised the development and expansion of the production of NBC overboots and supplied the Belgian and Danish armies.

1970

Founding of Bekina Indurub

Founding of Bekina Indurub

Georges founded Bekina Indurub, one of the first Belgian producers using injection-moulding technology for rubber. That resulted in technical, ergonomic and price advantages, in the market for slatted frames and ladder feet, for example. These are still two of Bekina Indurub's focus markets today.

1970

Georges Vanderbeke, second generation

Georges Vanderbeke, second generation

Denis's son Georges Vanderbeke joined the company. Georges harnessed his commercial acumen to develop the company’s market expertise with a view to growth and internationalisation. He commenced the production of pressed rubber safety boots and established sales outlets in Western Europe. This allowed Georges to lay the foundations for the globalisation of Bekina.

1962

Founding of Bekina (Boots) by Denis Vanderbeke

Founding of Bekina (Boots) by Denis Vanderbeke

The son of a shoemaker, Denis Vanderbeke learnt the tricks of the trade from an early age. Enterprising though he was, he chose not to follow in his father's footsteps. After all, every village already had a shoemaker. Instead, Denis spotted an opportunity to make his living from supplying the shoemakers with their materials. He familiarised himself with the burgeoning rubber boot business and decided to start manufacturing his own boots. He founded Bekina in 1962 and achieved huge success in Belgium and the Netherlands with his handmade rubber boots for farmers.